APPLICATION NOTE NO. 88

Frame Coating Repair for the

SBE 32 Carousel Water Sampler

April 2008

Print

version

Print

version

This Application Note reviews making repairs to

the coating on the frame of the SBE

32 Carousel Water Sampler.

Background

The SBE 32 Carousel’s frame is aluminum. The

frame components are coated with Plascoat® PPA 571ES, a polymer alloy

coating manufactured by Plascoat Systems Limited. PPA 571ES is a thermoplastic

coating powder, which melts to form a fusion-bonded coating. PPA 571ES is unlike

the thermosetting power paints normally associated with the powdercoat

process, as it does not undergo chemical cross-linking during the curing

process.

Damage (chips, scrapes, etc.) to the coating can

lead to corrosion of the frame. Additionally, use of the Carousel for trace

metal analysis of water samples requires that the aluminum frame be completely

encapsulated. The best method for repairing damage to the frame coating is to

have the part(s) stripped and recoated. However, this is not always practical;

this application note provides a method for repairing frames in the field, using

the PPA 571ES powder.

Notes:

- While other paints and materials may be

used to make cosmetic repairs to the frame parts, they are not likely to

completely adhere to the existing PPA 571ES coating, and may allow water to

penetrate, leading to corrosion of the aluminum frame. In addition, most other

coating products do not have the elasticity of the PPA 571ES, and are likely

to crack and flake when exposed to sea pressure; again, this will allow water

penetration, leading to corrosion of the aluminum frame.

- A copy of the current product data sheet for

PPA 571ES is included at the end of the

pdf version of this Application Note

for your convenience. See Plascoat’s website for the most up-to-date

specifications (www.plascoat.com/techdocs/datasheets/plascoat_ppa_571_es.htm).

Repairing Small Chips and Scrapes

This repair procedure applies only to small areas

of damage, where the coating has been pushed away from the surface rather

than scraped off of the surface. For example, a small gouge caused by a tool or

a small nick can be repaired using this technique.

Note: If there are multiple gouges or nicks on a

part, consider carefully removing the material around the gouges / nicks and

following the instructions for repairing larger damaged areas. It may be easier

to repair one large area than to repair many small gouges / nicks.

Recommended Tools and Supplies

- Soldering iron with clean tip, preferably

un-tinned (electric or propane)

- Heat gun, high temperature (648 °C

recommended); typically available at industrial supply shops (for example,

item #78864 Fully Adjustable Electronic Heat Gun from Griot’s Garage –

www.griotsgarage.com – was used by Sea-Bird for this repair procedure)

- Cellulose thinner or white spirit, for

degreasing

Procedure

- Clean the area of any salt residue.

- Clean / degrease the exposed metal using a

cellulose thinner or white spirit.

- Heat the outside edges of the damage, using

direct contact with the tip of the soldering iron. Use the tip of the

soldering iron to push the plastic material back together.

- Once the material has been pushed together,

smooth the material with the heat gun. Aim the heat gun directly at the

repair until enough heat is built up to allow the repaired material to flow

and smooth out. This will take quite some time, due to the large thermal mass

of the frame parts (in tests at Sea-Bird, it took approximately 5 minutes to

heat the part sufficiently for the material to flow and smooth out).

Repairing Larger Scrapes

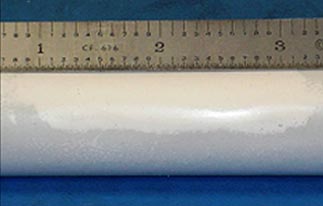

This procedure applies to larger areas of damage,

where the coating has been severely scraped and removed from the part (see photo

below).

Recommended Tools and Supplies

- Heat gun, high temperature (648 °C

recommended); typically available at industrial supply shops (for example,

item #78864 Fully Adjustable Electronic Heat Gun from Griot’s Garage –

www.griotsgarage.com – was used by Sea-Bird for this repair procedure)

- Propane torch (for extremely large areas)

- IR thermometer, to determine temperature of

repair area; typically available at industrial supply shops (for example, item

#50395 Infrared Laser Thermometer from Griot’s Garage ‑

www.griotsgarage.com – was used by Sea-Bird for this repair procedure)

- Metal file, for removing loose coating

- Sandpaper, non-metallic, varying grits, for

removing loose coating and sharp edges, and smoothing new coating

- Cellulose thinner or white spirit, for

degreasing

- Plascoat® PPA 571ES powder;

available from Sea-Bird in part number 50439 (Carousel Frame Powder Kit),

which contains 100 grams of the powder in a small container. The example

repair shown in the photos below used approximately 5 grams of the powder.

- Small flour sifter, for evenly dispersing

powder onto the metal surface

Procedure

- Completely remove all loose coating material

from the area to be repaired, using a metal file or sandpaper.

- Sand any burrs or gouges in the aluminum to

remove sharp edges.

- Clean / degrease the exposed metal with a

cellulose thinner or white spirit.

- Heat the exposed metal using a heat gun or

propane torch. Do not allow a direct flame to contact the undamaged coating

material; direct contact will damage and discolor the material. Use the IR

thermometer to monitor the temperature; a minimum temperature of 150 °C is

required for the powder to adhere to the part.

(In tests at Sea-Bird, it took

approximately 15 minutes to heat the part to 150 °C with a heat gun).

- Once the part has reached the required

temperature, carefully apply the PPA 571ES powder to the part. Sprinkle the

powder on evenly, in thin coats, using a small flour sifter. It is important

to build the repair slowly, with thin coats of powder. Continue to maintain

the heat on the part to allow the material to flow evenly. When enough powder

has been added to fill in the damaged area, allow the part to cool.

- When cool, the new coating can be treated

further to improve the appearance of the repair, if desired

(these steps improve the appearance of the repair, but are not

required):

- To match the contour of the surrounding

coating, sand the new coating.

- To restore the gloss to the coating,

heat the repaired and sanded area with the heat gun.

|

Coating scraped from frame part; damaged area approximately 2 inches (5 cm)

long. |

Repaired frame part.

Repair has been sanded and had heat applied to restore gloss finish

(steps 6A and 6B). |

Last modified:

05 May 2010

Sea-Bird Home Phone: (+1) 425-643-9866

Fax: (+1) 425-643-9954 E-mail:

seabird@seabird.com

![]()

![]()