APPLICATION NOTE NO. 57

Connector Care and Cable Installation

Revised

January 2014

Print

version

Print

version

The Application Note describes the proper care of connectors

and installation of cables for Sea-Bird instruments. The Application Note is divided into three sections:

Note: All photos in this

Application Note show standard Impulse XSG/AG connectors. Except as noted, all

procedures apply to standard XSG/AG connectors as well as to optional

wet-pluggable MCBH connectors.

Clean and inspect connectors, cables, and dummy

plugs:

- Before every cruise.

- During the cruise -- This is a good practice

if you have a few days of down time between casts.

- After every cruise -- This is the best way to

find and remove any corrosion on connector pins before severe corrosion

develops.

- As part of your yearly equipment maintenance.

Follow this procedure:

- Carefully clean the bulkhead connector and the inside of the

mating cable's boot or the dummy plug with a Kim wipe. Remove all grease, hair, dirt, and other contamination.

See Cautions in Step 3 regarding lubricants.

|

|

Clean bulkhead connector

|

Clean inside of cable boot or dummy plug

|

|

- Inspect the connector and cable boot or dummy

plug:

- Inspect the pins on the bulkhead connector for signs of

corrosion. The pins should be bright and shiny, with no discoloration. If the pins are discolored or corroded, clean

with alcohol and a Q-tip.

- Inspect the bulkhead connector for chips, cracks, or

other flaws that may compromise the seal.

- Inspect the cable boot or dummy plug for cuts, nicks, breaks, or other problems

that may compromise the seal.

Replace severely corroded or otherwise damaged connectors,

cables, and dummy plugs -- contact Sea-Bird for

instructions and a Return Material Authorization (RMA) number.

|

|

- Using a tube of 100% silicone grease (Dow DC-4

or equivalent), grease the bulkhead connector and the cable boot or dummy

plug:

CAUTIONS:

- For all connectors: Do not use WD-40 or other petroleum-based lubricants, as they

will damage the connectors.

- For optional wet-pluggable MCBH connectors: Silicone lubricants in a spray

can may contain ketons, esters, ethers, alcoholos, or glycols in their

propellant. Do not use these sprays, as they will damage the connectors.

Teledyne Impulse sells a silicone lubricant in a pump spray bottle that may

be used with these connectors.

|

|

- Squeeze the silicone grease --

approximately half the size of a pea -- onto the end of your finger. Apply a light, even coating of grease to the molded ridge around the base of the

bulkhead connector. The ridge looks like an O-ring molded into the bulkhead connector base and fits into the groove

of the mating cable boot or dummy plug.

|

Apply grease to molded ridge |

- Squeeze the silicone grease

-- approximately half the size of a pea -- onto the end of your finger. Apply

a light, even coating of grease to the inside of the cable boot or dummy plug.

|

Apply grease to inside of cable boot / dummy plug |

- Standard XSG/AG connectors only: Align the bump on the cable

boot or dummy plug with the large pin on the bulkhead connector, and

align the sockets with the pins.

Optional wet-pluggable MCBH connectors only: Align the non-conducting

guide pin and the conducting pins with the mating sockets.

- Do not twist the cable boot or dummy

plug on the bulkhead connector. Twisting can lead to bent pins, which

will soon break.

- Push the cable boot or dummy plug all the way onto the bulkhead

connector.

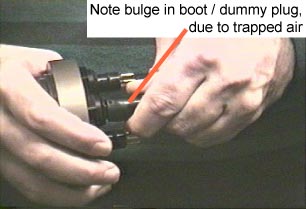

- Standard XSG/AG connectors only: You

may note a bulge in the boot or dummy plug, which is due to trapped air.

There may be an audible pop, which is good. With some newer cables or dummy

plugs, or in cold weather, there may not be an initial audible pop.

|

|

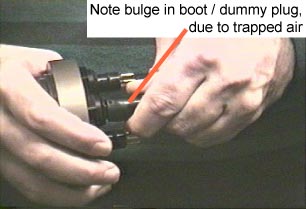

- Standard XSG/AG connectors only: After the cable or dummy plug is

mated, run your fingers along the cable boot or dummy

toward the bulkhead, milking any trapped air out of the boot or plug. You should hear the air being ejected.

CAUTION: Failure to eject the trapped air will result in the connector

leaking.

|

|

After the cable boot or dummy plug is mated

to the bulkhead connector, install the locking sleeve.

The locking sleeve secures the cable or dummy plug to the bulkhead connector and

prevents it from being inadvertently removed.

Important points regarding locking sleeves:

- Tighten the locking sleeve by hand. DO NOT use a wrench or pliers to tighten the locking sleeve.

Over-tightening will gall the threads, which can

bind the locking sleeve to the bulkhead connector. Attempting to remove a tightly bound locking sleeve may

instead result in the bulkhead connector actually unthreading from the end cap. A loose

bulkhead connector will lead to a

flooded instrument. Pay particular attention when removing a locking sleeve to

ensure the bulkhead

connector is not loosened.

- It is a common misconception that the locking sleeve provides

watertight integrity. It does not, and continued re-tightening of the locking sleeve will not

fix a leaking connector.

- As part of routine maintenance at the end of a day's

casts, remove the locking sleeve, slide it up the cable, and rinse the

connection

(still mated) with fresh water. This will prevent premature cable failure.

In cold weather, the cable or dummy plug may be hard to install and

remove.

Removing a Frozen Cable Boot or Dummy Plug:

- Wrap the cable boot or dummy plug with a washrag or other cloth.

- Pour hot water on the cloth and let the it sit for a

minute or two. The cable boot or dummy plug

should thaw and become flexible enough to be removed.

Installing a Standard XSG/AG Cable or Dummy Plug:

When possible, install cables and dummy plugs in warm environments.

If not,

warm the cable boot or dummy plug sufficiently so it is flexible. A

flexible cable boot or dummy plug will install properly.

Note about Wet-Pluggable (MCBH) Connectors:

As an option, Sea-Bird offers wet-pluggable

(MCBH) connectors in place of the standard Impulse XSG/AG connectors. Wet-pluggable connectors have a non-conducting guide

pin to assist pin alignment and require less force to mate, making them

easier to mate reliably under dark or cold conditions, compared to our

standard connectors. Wet-pluggable connectors may be mated in wet conditions;

their pins do not need to be dried before mating. By design, water on the

connector pins is forced out as the connector is mated. However, they must not

be mated or un-mated while submerged. Like standard connectors, wet-pluggables

need proper lubrication and require care during use to avoid trapping water in

sockets.

If desired, Sea-Bird can retrofit your existing instruments with

wet-pluggable connectors; contact Sea-Bird for pricing information.

Application Note Revision History

| Date |

Description |

| |

Initial release. |

| May 2003 |

- Update link to SBE Data Processing

on FTP site.

- Add information on .xmlcon file.

- Update screen capture for Data Conversion Miscellaneous tab.

- Update address. |

| August 2007 |

- Revise recommendations on how

frequently to unmate and check connectors.

- Add recommendations to lube inside of cable boot.

- Make more general (previously mentioned only I/O cables).

- Add description of wet-pluggable connectors in section dealing

with cold weather installation. |

| February 2010 |

- Update to include information

about MCBH connectors.

- Update address. |

| January 2014 |

- Update to include caution about

using silicone spray that contains propellants incompatible with

MCBH connectors. |

Sea-Bird Home Phone: (+1) 425-643-9866

E-mail:

seabird@seabird.com

![]()

![]()