Pressure Port Plug Removal, Oil Refill, & Nylon Capillary Fitting Installation

April 2001

FIELD SERVICE BULLETIN NO. 3

![]() Retrofit for SBE 37 MicroCATs with Optional Pressure

Sensor --

Retrofit for SBE 37 MicroCATs with Optional Pressure

Sensor --

Pressure Port Plug Removal, Oil Refill, & Nylon

Capillary Fitting Installation

April 2001

![]()

![]() Print version

Link to all Field Service Bulletins

Print version

Link to all Field Service Bulletins

SBE 37 MicroCATs (37-IM, 37-SM, and 37-SI) that meet all of the following criteria:

Note: This Field Service Bulletin does not apply to the SBE 37-IMP, 37-SMP, or 37-SIP.

The MicroCAT’s low pressure (< 1500 psia) Paine pressure sensor is made of stainless steel. When installed in the MicroCAT, the sensor is in electrical contact with the titanium end cap. The pressure sensor and end cap pressure port were originally filled with a silicon oil, and a pressure port plug was used to retain the oil. In some cases, there has been intrusion of salt water into the pressure sensor cavity, leading to corrosion.

This retrofit kit is being provided to prevent corrosion from occurring in the future. The kit consists of a pressure port capillary fitting to replace the pressure port plug and a higher viscosity oil.

|

Retrofit is simple and requires:

The retrofit procedure follows. |

|

P/N 50284 MicroCAT Retrofit Oil Fill Kit:

| P/N | Description | Quantity |

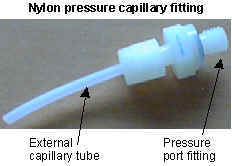

| 50283 | Nylon pressure capillary fitting | 1 |

| 30419 | Syringe for injecting DC-200 | 1 |

| 30420 | Needle (21 gauge) for syringe | 1 |

| 30421 | 76 mm (3 inch) long FEP tubing (1/32 inch I.D; 1/16 inch O.D.), to place on end of syringe needle | 1 |

| 31152 | Dow Corning DC-200 silicon oil (10,000 centistokes viscosity) | 1 ounce |

|

To replace the needle (if necessary):

|

|

|

Procedure:

|

|

|

|

|

|

|

|

|

|

|

|

Note: The oil in the nylon pressure capillary fitting transmits hydrostatic pressure to the pressure sensor inside the instrument, and prevents corrosion that might occur if the sensor diaphragm was exposed to water. Because of the viscosity of the silicone oil and capillary action, the silicone oil does not run out of the external capillary tube. However, due to temperature and pressure cycling over long periods, it is normal for some oil to slowly leak out of the external capillary tube. When the oil is not visible or is receding inside the translucent tube, or if the fitting has been damaged, refill the oil using the procedure described above.

![]()

Sea-Bird Home Phone: (+1) 425-643-9866 E-mail: seabird@seabird.com