Instructions for Care and Cleaning of Conductivity Cells

Revised March 2014

APPLICATION NOTE NO.

2D

Instructions for Care and Cleaning

of Conductivity Cells

Revised March 2014

![]()

This application note presents recommendations for cleaning and storing conductivity sensors. In the past, Sea-Bird had recommended cleaning and storing conductivity sensors with a Triton X-100 solution, and cleaning conductivity sensors with an acid solution. Our research leads us to recommend adding the use of a dilute bleach solution to eliminate growth of bio-organisms, and eliminating the use of acid in most cases.

The application note is divided into four sections:

Since any conductivity sensor’s output reading is proportional to its cell dimensions, it is important to keep the cell clean of internal coatings. Cell electrodes contaminated with oil, biological growths, or other foreign material will eventually cause low conductivity readings. To control growth of bio-organisms in the conductivity cell, follow these rinsing and cleaning recommendations:

No adverse effects have been observed as a result of dry storage, if the cell is rinsed or soaked with fresh, clean water before storage to remove any salt crystals. This leads to the following conductivity cell storage recommendations:

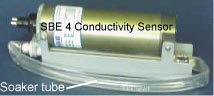

The Tygon tubing looped around the ends of the conductivity cell, whether dry or filled with a bleach or Triton solution, has the added benefit of keeping air-borne contaminants (abundant on most ships) from entering the cell.

Every conductivity calibration certificate has a frequency output for zero conductivity, obtained from a cell thoroughly rinsed in distilled or de-ionized water, with all the water shaken out (dry cell). A zero conductivity frequency that has changed by more than a few 10ths of a Hertz may indicate a cell that is damaged or considerably out of calibration. Noisy readings (± a few 10ths of a Hertz) indicate a dirty cell; follow the procedure for Cleaning Severely Fouled Sensors to clean a dirty cell.

Note: See

Cleaning Materials below for discussion of appropriate

sources / concentrations of water, Triton X-100, bleach, white vinegar, and tubing.

Note: See

Cleaning Materials below for discussion of appropriate

sources / concentrations of water, Triton X-100, bleach, white vinegar, and tubing.

CAUTIONS:

Active Use (after each cast)

- If not rinsed between uses, salt crystals may form on the conductivity cell platinized electrode surfaces. When the instrument is used next, sensor accuracy may be temporarily affected until these crystals dissolve.

- No danger of freezing: Fill the cell with a 500 – 1000 ppm bleach solution, using a loop of Tygon tubing attached to each end of the conductivity sensor to close the cell ends.

- Danger of freezing: Remove larger droplets of water by blowing through the cell. Do not use compressed air, which typically contains oil vapor. Attach a loop of Tygon tubing to each end of the conductivity cell to close the cell ends.

Routine Cleaning (no visible deposits or marine growths on sensor)

Routine Cleaning (no visible deposits or marine growths on sensor)

* If you do not have a large supply of fresh water: As a minimum, flush the cell with enough warm, fresh, clean water to fill the cell five times, or until rinsed thoroughly.

Cleaning Severely Fouled Sensors (visible deposits or marine growths on sensor)

- Thoroughly rinse in distilled or de-ionized water, and shake out all the water. With the conductivity cell dry, take and record a raw conductivity reading (in Hz). Compare to the zero conductivity frequency on the calibration sheet. The output should be within a few tenths of a Hz of the zero conductivity frequency. If not, proceed to Step 2.

If the zero conductivity is still outside the expected range, the conductivity cell may require factory cleaning.

Long-Term Storage (after field use)

- Storing the cell dry prevents the growth of any bio-organisms in water in the cell, thus preserving the calibration.

Water

De-ionized (DI) water, commercially distilled water, or fresh, clean, tap water is recommended for rinsing, cleaning, and storing sensors.

Where fresh water is extremely limited (for example, a remote location in the Arctic), you can substitute clean seawater for rinsing and cleaning sensors. If not immediately redeploying the instrument, follow up with a brief fresh water rinse to eliminate the possibility of salt crystal formation (salt crystal formation could cause small shifts in calibration).

Triton X-100

Triton X-100 is Octyl Phenol Ethoxylate, a mild, non-ionic surfactant (detergent). Triton X-100 is included with every CTD shipment and can be ordered from Sea-Bird, but may be available locally from a chemical supply or lab products company. It is manufactured by Avantor Performance Materials (see http://avantormaterials.com/commerce/product.aspx?id=2147509608). Other liquid detergents can probably be used, but scientific grades (with no colors, perfumes, glycerins, lotions, etc.) are required because of their known composition. It is better to use a non-ionic detergent, since conductivity readings taken immediately after use are less likely to be affected by any residual detergent left in the cell.

100% Triton X-100 is supplied by Sea-Bird; dilute the Triton as directed in Rinsing, Cleaning, and Storage Procedures.

Bleach

Bleach is a common household product used to whiten and disinfect laundry. Commercially available bleach is typically 4 % - 7% (40,000 – 70,000 ppm) sodium hypochlorite (Na-O-Cl) solution that includes stabilizers. Some common commercial product names are Clorox (U.S.) and eau de Javel (French).

Dilute to 500 – 1000 ppm. For example, if starting with 5% (50,000 ppm) sodium hypochlorite, diluting 50 to 1 (50 parts water to 1 part bleach) yields a 1000 ppm (50,000 pm / 50 = 1000 ppm) solution.

Tygon Tubing

Sea-Bird recommends use of Tygon tubing, because it remains flexible over a wide temperature range and with age. Tygon is manufactured by Saint-Gobain (www.tygon.com). It is supplied by Sea-Bird, but may be available locally from a chemical supply or lab products company.

Keep the Tygon in a clean place (so that it does not pick up contaminants) while the instrument is in use.

White Vinegar

White vinegar is a common household product used to dissolve mineral deposits, and may be used to remove minor mineral contamination of the conductivity cell. Commercially available white vinegar is typically 5 – 8% acetic acid (CH3COOH) in aqueous solution; verify that there are no oils or other ingredients.

- Place a 0.6 m (2 ft) length of Tygon tubing over the end of the conductivity cell.

- Clamp the instrument so that the cell is vertical, with the Tygon tubing at the bottom end.

- Loop the Tygon tubing into a U shape, and tape the open end of the tubing in place at the same height as the top of the glass cell.

- Pour weak white vinegar solution (1 part white vinegar, 2 parts water) into the open end of the tubing until the cell is nearly filled. Let it soak for 2-3 minutes only.

- Drain the solution from the cell and flush for 5 minutes with warm (not hot), clean, de-ionized water.

- Rinse the exterior of the instrument to remove any spilled solution from the surface.

- Fill the cell with a 1% Triton X-100 solution and let it stand for 5 minutes.

- Drain and flush with warm, clean, de-ionized water for 1 minute.

- Carefully remove the 0.6 m (2 ft) length of Tygon tubing.

Hydrochloric Acid (HCl)

Many years ago, Sea-Bird recommended cleaning with a hydrochloric acid (HCl) solution to eliminate bio-organisms or mineral deposits on the inside of the cell. However, bleach cleaning has proven to be effective in eliminating growth of bio-organisms, and is much easier to use and dispose of than acid. Data from many years of use shows that mineral deposits are an unusual occurrence. Sea-Bird recommends that, in most cases, hydrochloric acid should not be used to clean the conductivity sensor. In rare instances, it may still be required for mineral contamination of the conductivity cell. Sea-Bird recommends that you return the equipment to the factory for this cleaning. Information below is provided if you cannot return the equipment to Sea-Bird.

CAUTIONS:

WARNING! Observe all precautions for working with strong acid. Avoid breathing acid fumes. Work in a well-ventilated area.

The acid cleaning procedure for the conductivity cell uses approximately 50 - 100 cc of acid. Sea-Bird recommends using a 20% concentration of HCl. However, acid in the range of 10% to full strength (38%) is acceptable.

|

- Place a 0.6 m (2 ft) length of Tygon tubing over the end of the cell.

- Clamp the instrument so that the cell is vertical, with the Tygon tubing at the bottom end.

- Loop the Tygon tubing into a U shape, and tape the open end of the tubing in place at the same height as the top of the glass cell.

- Pour 10% to 38% HCl solution into the open end of the tubing until the cell is nearly filled. Let it soak for 1 minute only.

- Drain the acid from the cell and flush for 5 minutes with warm (not hot), clean, de-ionized water.

- Rinse the exterior of the instrument to remove any spilled acid from the surface.

- Fill the cell with a 1% Triton X-100 solution and let it stand for 5 minutes.

- Drain and flush with warm, clean, de-ionized water for 1 minute.

- Carefully remove the 0.6 m (2 ft) length of Tygon tubing.

| Date | Description |

| January 1998 | Initial release. |

| October 2002 | Remove reference to part number for small anti-foul cylinders (which have been eliminated) in Tygon tubing. |

| January 2005 | Change in recommendations.: Clean with bleach solution as well as Triton. Acid cleaning is not recommended in general, but some information on acid is still provided for the few cases where it is necessary. A section on Materials added, defining water, Triton, etc. in more detail. |

| July 2005 | Include information on common names of commercially available bleach. |

| October 2006 | Update manufacturer name and website link for Triton. |

| September 2008 | Add SBE 52-MP to list of instruments with integral, internal pump that should not have acid cleaning. |

| October 2010 | - Add reference to IDO MicroCATs, with

caution to following cleaning and storage procedures in Application

Note 64 instead of in this application note. - Update address. |

| October 2012 | - Update manufacturer information for Triton. - Add information on 25plus. - Add reference to ODO MicroCATs, with caution to following cleaning and storage procedures in ODO manual instead of in this application note. - Eliminate ‘new’ language regarding cleaning and storing, since recommendations date from 2006. |

| March 2014 | - Add information on cleaning with

white vinegar. - Add information on checking zero conductivity frequency to verify cleanliness. - Add information on cleaning if SBE 63 Optical Dissolved Oxygen Sensor on system. - Update language on recent recommendations (which dated back to 2005). |

![]()

Sea-Bird Home Phone: (+1) 425-643-9866 E-mail: seabird@seabird.com