![]()

|

|

Rapid progress in the development of satellite, RF, and cell-phone telemetry has made real-time, unattended, remote oceanography increasingly practical. However, before these telemetry techniques can be exploited, the data must first be brought to the surface. Traditionally, underwater-to-surface data transmission was accomplished using direct cable connections. Such cables are bulky, expensive, and unreliable, and the positions (and number) of individual sensors are fixed once the cable is designed and manufactured. More recently, acoustic telemetry has been investigated as a substitute for direct cables. However, acoustic methods result in an even more costly and complex system; additional battery packs are required, depth is restricted due to limited transmission range, and they are subject to a multitude of error sources and failure modes. Today's inductive modem technology provides a convenient, economical, and reliable solution while still maintaining flexibility; Sea-Bird's solution permits up to 100 instruments to be positioned or repositioned at any depth (Figure 1). For typical salt water applications, the maximum mooring depth is 7000 meters; see Fresh-Water Inductive Mooring (Section IVE) for fresh water limitation. |

II. Description of Inductive Modem

The Inductive Modem (IM) System (or 'Inductively Coupled Modem') employs the mooring cable as its transmission medium, eliminating the need for additional conductors. An Inductive Modem Module (IMM) transmits sensor data to the surface by applying a signal to the internal winding of a cable coupler. This induces a signal in the single-turn secondary winding formed by the mooring cable passing through the coupler. The signal is retrieved at the surface by a similar configuration. Each coupler is made up of two halves, allowing it to simply clamp around the cable as opposed to having to thread the cable through the unit.

Each cable coupler contains a transformer that magnetically couples the IMM to the mooring cable. Transformers cannot operate at zero frequency (DC) and are inefficient at very low frequencies; although it is improbable that the serial data will consist of all ones or zeros, the IM system needs to account for this possibility. To allow reliable transmission of such data, it is impressed upon a high-frequency carrier waveform. The carrier encoding is performed by MODEM devices (from MODulator-DEModulator), which modulate the carrier at the data source and demodulate it at reception back into the serial form for use by the target PC or CPU.

Sea-Bird’s Inductive Modem uses the Differential Phase Shift Keying (DPSK) technique to achieve efficient data transmission with low error rates. It is the same method employed by the widely proven SBE 911plus CTD system, but operating at a lower baud rate (1200 vs. 8640).

The Sea-Bird IM DPSK system uses a carrier frequency of 4800 Hz, allotting four cycles of the carrier frequency to each data bit. The encoding scheme is straightforward: if the next bit is a one, the phase of the carrier is inverted (shifted 180 degrees); if the next bit is a zero, the carrier phase does not change.

The modulation and demodulation hardware required for DPSK are extremely simple. Modulation requires only an OR gate and flip-flop; demodulation is inherently coherent (bit energy is averaged rather than spot-sampled) using minimal hard logic, a shift register implementing a one-bit delay being the principle component. Sending data containing all-zeros results in a single continuous frequency (4800 Hz) being placed on the transmission cable, which is readily detected by IM instruments as the wake-up signal. The IM system is designed to be insensitive to the connection polarity of the coupling transformers.

Each cable coupler contains a transformer. The toroidal transformer consists of a circular ferrite core and two coils which share a magnetic field. By applying an AC voltage to an 8-turn primary winding, a voltage of half the amplitude will be induced in a 4-turn secondary winding, as shown in Figure 2.

Figure 3 illustrates the operation of such a transformer in the context of the Direct Connection Inductive Mooring (Section IVB). This is conceptually the simplest configuration, with only a single cable coupler. Both the surface modem and lower end of the mooring cable are grounded to the seawater, completing the current loop through the mooring cable. Note that the secondary winding (in this case, the mooring cable) does not have to be wound tightly around the transformer core. The winding must only pass through the core.

The Typical Inductive Mooring (Section IVa) directly grounds both ends of the mooring cable to seawater, and the surface modem communicates inductively via the Inductive Cable Coupler (ICC) . When an IMM impresses a signal on the 100-turn winding, current flows around the loop formed by the mooring cable and seawater. At the surface, an ICC senses the current in the mooring cable and transmits it to the receiving IMM (shown pictorially in Figure 4 and schematically in Figure 5.)

|

|

|

|

|

|

|

A. Typical Inductive Mooring A typical ocean mooring is shown schematically in Figure 6. The mooring cable is a plastic-jacketed galvanized steel wire rope, a type frequently used for non-inductive oceanographic moorings because of the corrosion resistance provided by the plastic jacket. The ends of the wire rope are terminated with steel thimbles or swaged eye terminals. Deep moorings typically employ synthetic line below the lowest instrument. Individual inductive modem instruments may be clamped along the mooring cable at any position. It is not necessary to break the cable at the instrument positions or to provide any electrical connection between instrument and cable. Each instrument can be freely moved up or down the cable. The surface buoy contains a Sea-Bird Inductive Modem Module (IMM; see Section VC) that communicates with the underwater components via a through-hull bulkhead connector, polyurethane cable, and Sea-Bird Inductive Cable Coupler (ICC; see Section VD). As with the IM instruments, the ICC simply clamps anywhere along the plastic-jacketed portion of mooring cable below the seawater ground — no electrical connection to the mooring cable is required. The buoy controller / CPU (not supplied by Sea-Bird) links to the IMM using RS-232, enabling bi-directional half-duplex communication with the entire suite of IM instruments. |

|

|

B. Direct Connection Inductive MooringA second configuration makes use of a direct electrical connection between the surface buoy and the top of the mooring cable, as shown in Figure 7. In this configuration, the plastic-jacketed cable is brought inside the buoy. The buoy must be mechanically secured to the top of the cable without compromising the electrical insulation of the plastic jacket. The IMM connects to both the galvanized steel wire rope and to the buoy hull (or other seawater return) via a small Direct Connection PCB, co-located with the IMM inside the buoy. The ICC is eliminated, but connecting the buoy to the mooring cable may be more complicated.

|

|

|

C. Cable-to-Shore Inductive MooringAs shown in Figure 8, instruments may be placed at any position along a plastic-jacketed wire rope leading from shore. Here the problem of insulating the inner conductor at the shore end is easily solved, making the direct-connection approach to the IMM (Figure 7) the preferred method. |

|

|

D. Through-Ice Inductive MooringFigure 9 shows a mooring for through-ice applications. Both ends of the mooring cable must be immersed in the seawater to complete the circuit.

|

|

|

E. Fresh Water Inductive Mooring Figure 10 shows a mooring for fresh-water applications, for a mooring with an Inductive Cable Coupler (ICC). Due to the lower conductivity of fresh water, more exposed metal area is needed at both ends of the mooring line to complete the circuit. In fresh water, do not rely on the grounds provided by the eye or clevis alone. Use at least a 0.7 m (2 ft) length of 2 inch (outer diameter) or larger conductive pipe (galvanized or stainless steel) as top and bottom electrodes. Strip the ends of the mooring cable and clamp them to the pipes. Do not let the electrode pipe lie on the bottom; clamp the pipe to the mooring line at least 2 or 3 meters above the bottom. A mooring with this design should provide good communications over 1000 meters of mooring line in water with conductivity as low as 100 µS/cm. For a mooring using a direct cable connection at the surface (no ICC), the connection to the buoy is as shown in Figure 7; several square feet of un-painted surface on the buoy is required to provide the large electrode at the top. The bottom connection remains as shown in Figure 10.

|

V. Inductive Modem System Components

|

|

A. Mooring Cable (not supplied by Sea-Bird) Mooring cables are usually polyethylene-jacketed galvanized steel wire rope. Provision for electrical contact with the water must always be made at the lower end of the cable. Typically, a few centimeters of insulation are removed and a swaged eye terminal (Figure 11) is installed, providing both a means of mechanical attachment and a suitable seawater ground. Mooring cable and cable assembly sources are given in Section VI. |

|

|

B. Underwater SensorsThe IM system supports both autonomously operating sensors and those that require a command to take a sample and return the data. Even with the IM connection, it is advantageous for IM sensors to store measurement data internally so that the data can be directly extracted from the instruments in the event of a failure of any part of the communications link (telemetry components, buoy, or IM). A further advantage to this scheme is that a series of samples can be retrieved for re-transmission, for example the most recent 16 samples, thereby minimizing the number of individual queries and maximizing battery life. For this to be successfully implemented, the sensor must be capable of communicating with the IM independently of acquiring data or timing its data collection to avoid conflict with IM inquiries. 1. Sea-Bird MicroCAT CT (pressure optional) Recorder, SBE 37-IM, 37-IMP, 37-IMP-IDO, and 37-IMP-ODO The SBE 37-IM, 37-IMP, 37-IMP-IDO, and 37-IMP-ODO (Figure 12) are CT (pressure optional) recorders, with internal batteries and FLASH memory, for depths to 7000 meters (with titanium housing). The MicroCATs can be commanded to sample via the IM link. However, it is usually desirable to make use of the MicroCAT's Autonomous Mode based on its internal clock and memory. In this mode, samples are taken and recorded in memory at fixed time intervals, while the buoy uses the IM link to request the most recent results. The SBE 37-IMP combines the features of the 37-IM with an integral, internal pump. The 37-IMP-IDO includes the pump as well as an Integrated Dissolved Oxygen (membrane-type) sensor, while the 37-IMP-ODO includes the pump as well as an integrated Optical Dissolved Oxygen sensor. |

|

|

2. Sea-Bird Temperature (pressure optional) Recorder, SBE

39-IM The SBE 39-IM (Figure 13) is a Temperature (pressure optional ) recorder, with internal batteries and FLASH memory, for depths to 10,500 meters (with titanium housing). It operates in command or autonomous mode, similar to the MicroCAT.

|

|

|

3. Sea-Bird SeaCAT CT (pressure optional) Recorder, SBE 16plus-IM V2 The 16plus-IM V2 (Figure 14) is a CT (pressure optional) recorder, with internal batteries and FLASH memory, for depths to 7000 meters (with titanium housing). It has six A/D input channels and one RS-232 input channel for auxiliary sensors. The 16plus-IM V2 operates in command or autonomous mode, similar to the MicroCAT.

|

|

|

4. Equipment manufactured by other companies,

interfacing with a Sea-Bird Underwater Inductive Modem Module (UIMM)

or SBE 44

Underwater Inductive Modem (Figure 15)

The UIMM is a small underwater module containing an IMM, inductive cable coupler, and cable clamp. It allows a variety of RS-232 serial output instruments to be integrated with an IM system. The UIMM contains no batteries, and must be powered by the serial output instrument or by an external battery pack The SBE 44 has a built-in inductive cable coupler and cable clamp, and contains a real-time clock, buffer memory, RS-232 interface, and internal batteries. It allows a variety of RS-232 serial output instruments to be integrated with an IM system. If the serial output instrument has modest power requirements, the SBE 44 can provide the power as well as the telemetry interface. The SBE 44, an older instrument, has more limited interface capabilities than the UIMM.

|

|

|

5. Equipment manufactured by other companies, incorporating built-in Sea-Bird

OEM IM components Other companies can purchase an Inductive Modem Module (IMM) and a cable coupler, for integration in their own instruments at the development stage. Figure 16 shows two examples of this integration. See OEM Components Available from Sea-Bird (Section VII) for additional integration information. Note: Voltage output (analog) or frequency output sensors cannot be directly interfaced to the IM system.

|

|

|

C. Inductive Modem Module (IMM)The IMM is a small printed circuit card (Figure 17) mounted in the surface buoy or on-shore (for cable-to-shore systems). When using the IMM in a Direct Connection configuration (Direct Connection and Cable-to-Shore moorings, Figures 7 and 8), it must be paired with Sea-Bird’s Direction Connection PCB to make a good electrical interface to the mooring cable. The Direct Connection PCB is co-located with the IMM (Figure 18). IMM Specifications |

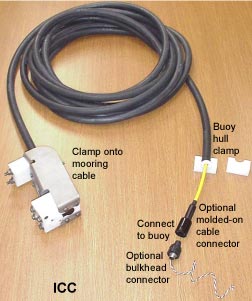

Figure 19: Inductive Cable Coupler (ICC) |

D. Inductive Cable Coupler (ICC)The ICC (Figure 19) is used with the IMM for moorings similar to Figures 6, 9, and 10. The ICC is available in a number of sizes, for clamping to mooring cables with diameters from 1/4 inch to 16 mm. The ICC cable can be specified for the desired length, with a pigtail or a molded connector.

|

The buoy controller is typically a microprocessor that schedules interrogation of the underwater instruments, interfaces to any desired atmospheric sensors, and controls the telemetry of data back to shore via RF, cell phone, satellite, or hard-wire link.

The surface buoy’s CPU controller connects via RS-232 to the local Sea-Bird IMM. Although the IMM is configured by default to communicate with the CPU at 9600 baud full duplex, the IMM communicates with the underwater sensors using a half-duplex 1200 baud telemetry link. Commands to and replies from IM instruments are sequential, not simultaneous. Commands may be issued globally or to an individual sensor. Global commands are processed by all IM instruments on the IM line, but the IM instruments do not send replies. These commands are typically used to set all IM instruments to the same time and date, or to instruct all IM sensors to begin sampling now or at some time in the future. To allow for individual instruments to receive commands and to reply, each instrument is programmed with an ID number in the sequence 00 to 99. Addressed commands can be used to instruct individual sensors to acquire data, check sensor status, or transmit stored data.

IM instruments usually reside in one of three operating modes: sleep, IM Service, and Host Service. The mode of operation is not user settable and depends on the action being performed by the IMM. Throughout most of each deployment, the IMM will be in sleep mode. Upon command from the buoy CPU, the surface IMM sends a wake-up signal that sets all instruments to IM Service mode. In IM Service mode, IM instruments respond to both global and individual commands sent over the IM line; if no commands are received within two minutes of wake-up, an internal time-out re-establishes Sleep mode. Host Service mode is entered when communication is initiated by the local sensor to store data, change settings, etc. While in Host Service mode, the IMM does not respond to (buoy controller) commands on the IM Line. If no communication is detected from the local instrument for two minutes, the IMM re-enters Sleep mode. For power requirements, see Inductive Modem System Components – Inductive Modem Module (VC above).

|

|

F. Surface Buoy (not supplied by Sea-Bird)The surface buoy houses the Inductive Modem Module, Buoy Controller / Data Logger, telemetry transmitter / receiver, and necessary batteries (Figure 20). |

G. Shore Installation (not supplied by Sea-Bird)

Located on shore is the telemetry receiver (and in some cases a transmitter permitting shore-side control of buoy function), and a computer for logging, processing, and displaying buoy data.

VI. Resources for Mooring Cable, Cable Assemblies, and other Mooring System Components

A. Jacketed Wire Cable

Sea-Bird recommends a 3x19 strand oceanographic wire rope with protective polypropylene jacketing. Two sources for suitable jacketed wire are listed below; similar cable may also be available from other sources.

B. Mooring Hardware and Design Assistance

Mooring Systems, Inc. (+1 508-564-4770, sales@mooringsystems.com, www.mooringsystems.com) -- Terminated wire, cable assemblies, other mooring hardware, and mooring design assistance

C. Custom Mooring Systems

Custom mooring systems incorporating Sea-Bird Inductive Modem components have been manufactured by:

|

|

Qualified manufacturers of serial-output sensors can obtain IMM circuit cards and other components needed to convert new or existing instruments to IM operation. The IMM boardset is available with electrical pins on the bottom, to plug into electrical connections below it (as shown in Figure 17), or can be configured with the pins oriented for side connections. The IMM operates with supply voltages ranging from 7 to 25 VDC, and is compatible with battery packs typically used in ocean instruments. A high-voltage input adapter board is available for applications with input voltages from 20 to 80 VDC (Figure 21). The data interface is full duplex RS-232. The baud rate is user-programmable to 1200, 2400, 4800, 9600, or 19200 baud. In addition to the IMM, a split toroid core and transformer winding is required. In designing the mechanical mount for the IM coupler, note that one half of the toroid is to be captured within the instrument and surrounded by the free-standing winding. Single-pin seal pins (not supplied) are typically used to support the winding and bring the electrical connections into the instrument. The winding and core half are then urethane potted. The potting material must adhere to the seal pins; no other adhesive bonds are critical. The winding is entirely surrounded by the potting material, so that water intrusion along the toroid surface is of no consequence. The toroid itself is unaffected by water exposure. The OEM must make provisions to lightly clamp the other toroid half into position. Figure 22 shows various aspects of the basic design. Additional details and design assistance are available from Sea-Bird. |

|

|

As an alternative to making the IM coupler an integral part of an end cap, the Inductive Cable Coupler (ICC, Figure 19) can be connected to a bulkhead connector on the OEM instrument (Figure 23), making the IM coupling a flexible lead of any convenient length. |

| Date | Description |

| May 2011 | Initial release as an application note (was previously available in our Technical Papers list). Add information on 37-IMP-IDO, and update list of mooring system vendors. |

| October 2012 | Add information on 37-IMP-ODO. |

| December 2013 | Remove Sound Ocean Systems from list of Custom Mooring System suppliers. |

![]()

Sea-Bird Home Phone: (+1) 425-643-9866 E-mail: seabird@seabird.com