SBE 37 MicroCATs and SBE 49 FastCATs with Plastic Housing Option

July 2008

FIELD SERVICE BULLETIN NO. 15

![]() Alert and Handling Precautions --

Alert and Handling Precautions --

SBE 37

MicroCATs and SBE 49 FastCATs with Plastic Housing Option

July 2008

![]()

![]() Print version

Link to all Field Service Bulletins

Print version

Link to all Field Service Bulletins

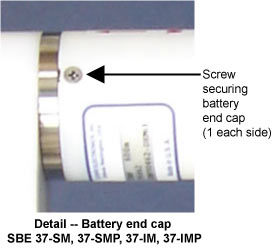

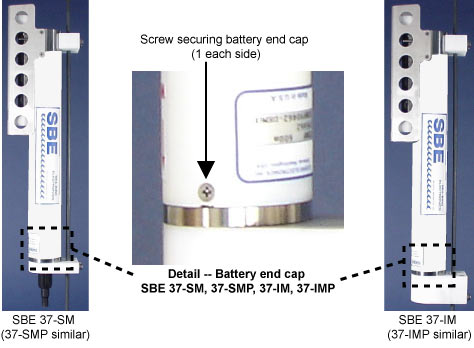

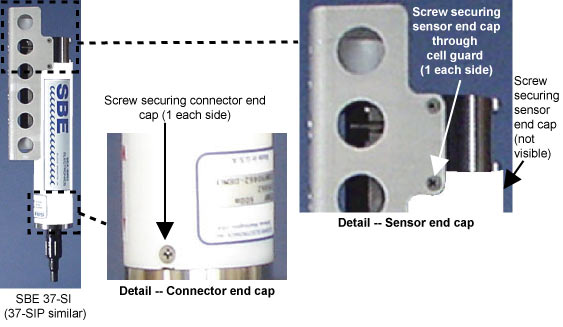

All MicroCATs (SBE 37-SM, 37-SMP, 37-IM, 37-IMP, 37-SI, and 37-SIP) and all SBE 49 FastCATs with the optional 250-meter plastic housing.

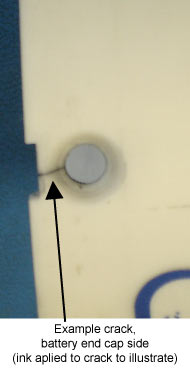

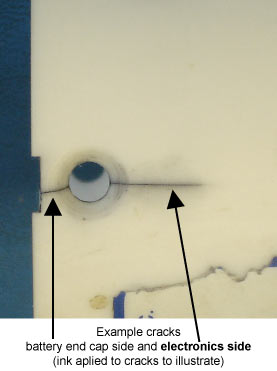

| Prior to deployment / redeployment, inspect all MicroCATs (with plastic housings) for cracks around the two screw holes that retain the battery end cap (SBE 37-SM, -SMP, -IM, and -IMP). To check for cracking, use a magic marker and color the housing liberally around the two screw holes in the housing. When both holes have been marked, use a cloth or paper towel dipped in isopropyl alcohol to wipe the marker off of the housing’s surface. If there are cracks in the housing, the marker will have wicked into the cracks, and the cracks will become visible. |

|

|

|

|

|

Background information, handling precautions, and a summary of Sea-Bird’s correction action for all plastic MicroCAT and FastCAT housings are provided below.

The substitution of a 250-meter plastic housing for the standard 7000-meter titanium housing saves money and weight. However, more care and caution in handling is required with the plastic housing, when compared to the standard titanium housing. A few MicroCAT housings have been returned to Sea-Bird with cracks around battery end cap screw holes, as shown above.

Handling Precautions

- When removing the end cap (to replace batteries and/or access electronics), avoid any impact in this area of the housing.

- When reinstalling the end cap, do not use excess torque on the screws. Sea-Bird recommends tightening the screws to 15 inch-lbs. Alternatively, tighten finger-tight, and then turn each screw an additional 45 degrees.

If you remove the screws securing the conductivity cell guard to the housing (not typically done by the customer), follow the same precautions as described above for removing and replacing the battery end cap.

- When removing end caps (to access electronics), avoid any impact in this area of the housing.

- When reinstalling end caps, do not use excess torque on the screws. Sea-Bird recommends tightening the screws to 15 inch-lbs. Alternatively, tighten finger-tight, and then turn each screw an additional 45 degrees.

- When removing end caps (to access electronics), avoid any impact in this area of the housing.

- When reinstalling end caps, do not use excess torque on the screws. Sea-Bird recommends tightening the screws to 15 inch-lbs. Alternatively, tighten finger-tight, and then turn each screw an additional 45 degrees.

- Of primary concern are scratches on O-ring mating and sealing surfaces. Use extra care to avoid a scraping contact with these surfaces when replacing batteries and/or re-seating the end cap(s).

- Take care to keep O-ring lubricated surfaces clean – avoid trapping any sand or fine grit that can scratch the critical sealing surfaces. If the O-ring lubricant does accumulate any material or grit that can cause a leak or make a scratch, it must be carefully cleaned and replaced with fresh, clean lubricant (Parker Super O Lube).

- Shallow, external scratches are cosmetic only, and will not affect the performance of the instrument. However, deep external scratches can become points of weakness for deep deployments or fracture from impact during very cold weather.

See the applicable instrument manual for detailed step-by-step procedures for removing the instrument’s end cap(s).

Corrective Action by Sea-Bird

Sea-Bird plans to modify the existing end cap screw holes and screws in all plastic MicroCAT and FastCAT housings, to reduce the potential for cracks caused by over-torqueing. Sea-Bird will perform these modifications at no charge, under normal warranty conditions.

Summarizing:

Please contact Sea-Bird for an RMA number before sending the instrument.

![]()

Sea-Bird Home Phone: (+1) 425-643-9866 E-mail: seabird@seabird.com