APPLICATION NOTE NO. 71

Desiccant Use and Regeneration (drying)

Revised March 2008

Print version

Print version

This

application note applies to all Sea-Bird instruments intended for underwater

use. The application note covers:

- When

to replace desiccant

- Storage

and handling of desiccant

- Regeneration

(drying) of desiccant

- Material

Safety Data Sheet (MSDS) for desiccant

When to Replace Desiccant Bags

Before

delivery of the instrument, a desiccant package is placed in the housing, and

the electronics chamber is filled with dry Argon. These measures help prevent

condensation. To ensure proper functioning:

-

Install

a new desiccant bag each time you open the housing and expose the

electronics.

-

If

possible, dry gas backfill each time you open the housing and expose the

electronics. If you cannot, wait at least 24 hours before redeploying, to

allow the desiccant to remove any moisture from the chamber.

What

do we mean by expose the electronics?

- For most battery-powered Sea-Bird instruments (such as SBE 16,

16plus, 16plus

V2,

16plus-IM,

16plus-IM V2, 17plus,

19, 19plus, 19plus V2, 25, 26,

26plus, 37-SM,

37-SMP, 37-IM,

37-IMP, 44,

53,

54,

55,

Auto Fire Module

[AFM]), there is a bulkhead between the battery and electronics

compartments.

Battery

replacement does not affect desiccation of the electronics, as the batteries

are removed without removing the electronics and no significant gas exchange

is possible through the bulkhead. Therefore, opening the battery compartment

to replace the batteries does not expose the electronics; you do not need to

install a new desiccant bag in the electronics compartment each time you

open the battery compartment. For these instruments, install a new desiccant

bag if you open the electronics compartment to access the printed circuit

boards.

- For the SBE 39,

39-IM, and 48,

the electronics must be removed or exposed to access the battery. Therefore,

install a new desiccant bag each time you open the housing to replace a

battery.

Storage and

Handling

|

Testing

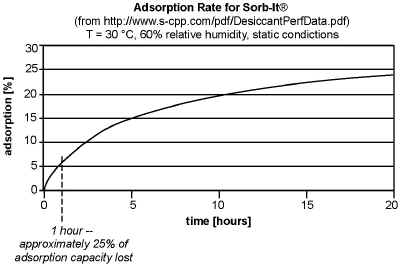

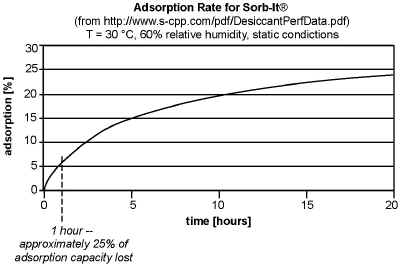

by Süd-Chemie (desiccant’s manufacturer) at 60% relative humidity and 30 °C

shows that approximately 25% of the desiccant’s adsorbing capacity is used up

after only 1 hour of exposure to a constantly replenished supply of moisture in

the air. In other words, if you take a bag out of a container and leave it out

on a workbench for 1 hour, one-fourth of its capacity is gone before you ever

install it in the instrument. Therefore:

- Keep

desiccant bags in a tightly sealed, impermeable container until you

are ready to use them. Open the container, remove a bag, and quickly

close the container again.

- Once

you remove the bag(s) from the sealed container, rapidly install the

bag(s) in the instrument housing and close the housing.

Do not use the desiccant

bag(s) if exposed to air for more than a total of 30 minutes.

|

|

Regeneration

(drying) of Desiccant

Replacement desiccant bags are available from Sea-Bird:

- PN

60039 is a metal can containing 25 1-gram desiccant bags and 1 humidity

indicator card. The 1-gram bags are used in our smaller diameter housings,

such as the SBE 3 (plus,

F, and S),

4 (M and C),

5T and 5P, 37 (-SI,

-SIP,

-SM,

-SMP, -IM,

and -IMP),

38, 39,

39-IM,

43, 44,

45, 48,

49, and 50.

- PN

31180 is a 1/3-ounce desiccant bag, used in our SBE 16plus, 16plus

V2,

16plus-IM,

16plus-IM V2,

19plus, 19plus V2,

21, and

52-MP.

- PN

30051 is a 1-ounce desiccant bag. The 1-ounce bags are used in our larger

diameter housings, such as the SBE 9plus,

16, 17plus,

19, 25,

26,

26plus, 32,

53 BPR,

54,

55,

AFM,

and PDIM.

However,

if you run out of bags, you can regenerate your existing bags using the

following procedure provided by the manufacturer (Süd-Chemie Performance

Packaging, a Division of United Catalysts, Inc.):

MIL-D-3464

Desiccant Regeneration Procedure

Regeneration

of the United Desiccants’ Tyvek Desi Pak® or Sorb-It®

bags or United Desiccants’X-Crepe Desi Pak® or Sorb-It®

bags can be accomplished by the following method:

- Arrange

the bags on a wire tray in a single layer to allow for adequate air flow

around the bags during the drying process. The oven’s inside temperature

should be room or ambient temperature (25 – 29.4 °C [77 – 85 °F] ). A

convection, circulating, forced-air type oven is recommended for this

regeneration process. Seal failures may occur if any other type of heating

unit or appliance is used.

- When

placed in forced air, circulating air, or convection oven, allow a minimum

of 3.8 to 5.1 cm (1.5 to 2.0 inches) of air space between the top of the

bags and the next metal tray above the bags. If placed in a radiating

exposed infrared-element type oven, shield the bags from direct exposure to

the heating element, giving the closest bags a minimum of 40.6 cm (16

inches) clearance from the heat shield. Excessive surface film temperature

due to infrared radiation will cause the Tyvek material to melt and/or the

seals to fail. Seal failure may also occur if the temperature is allowed to

increase rapidly. This is due to the fact that the water vapor is not given

sufficient time to diffuse through the Tyvek material, thus creating

internal pressure within the bag, resulting in a seal rupture. Temperature

should not increase faster than 0.14 to 0.28 °C (0.25 to 0.50 °F) per

minute.

- Set

the temperature of the oven to 118.3 °C (245 °F), and allow the bags of

desiccant to reach equilibrium temperature. WARNING:

Tyvek has a melt temperature of 121.1 – 126.7 °C (250 – 260 °F) (Non

MIL-D-3464E activation or reactivation of both silica gel and Bentonite clay

can be achieved at temperatures of 104.4 °C [220 °F]).

- Desiccant

bags should be allowed to remain in the oven at the assigned temperature for

24 hours. At the end of the time period, the bags should be immediately

removed and placed in a desiccator jar or dry (0% relative humidity)

airtight container for cooling. If this procedure is not followed precisely,

any water vapor driven off during reactivation may be re-adsorbed during

cooling and/or handling.

- After

the bags of desiccant have been allowed to cool in an airtight desiccator,

they may be removed and placed in either an appropriate type polyliner

tightly sealed to prevent moisture adsorption, or a container that prevents

moisture from coming into contact with the regenerated desiccant.

NOTE:

Use

only a metal or glass container with a tight fitting metal or glass lid to store

the regenerated desiccant. Keep the container lid closed

tightly to preserve adsorption properties of the desiccant.

Material

Safety Data Sheet (MSDS)

Last modified:

14 Oct 2010

Sea-Bird Home Phone: (+1) 425-643-9866

Fax: (+1) 425-643-9954 E-mail:

seabird@seabird.com

![]()

![]()